Gausium Scrubber 75P

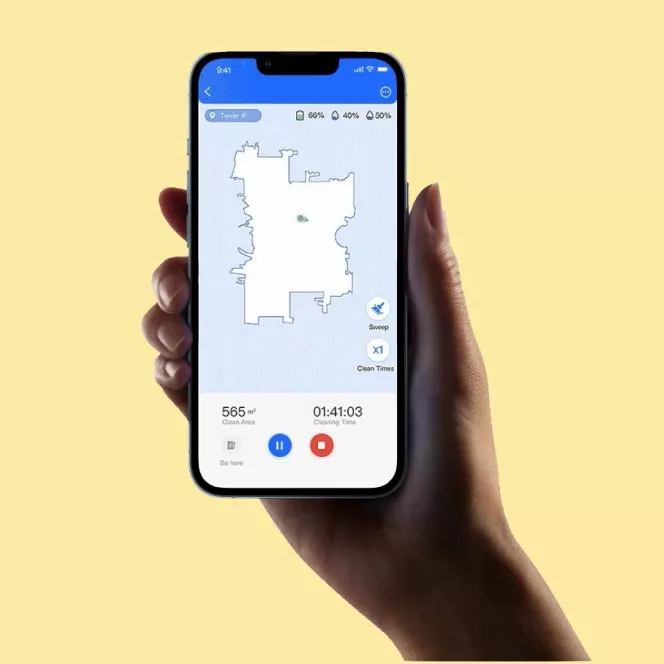

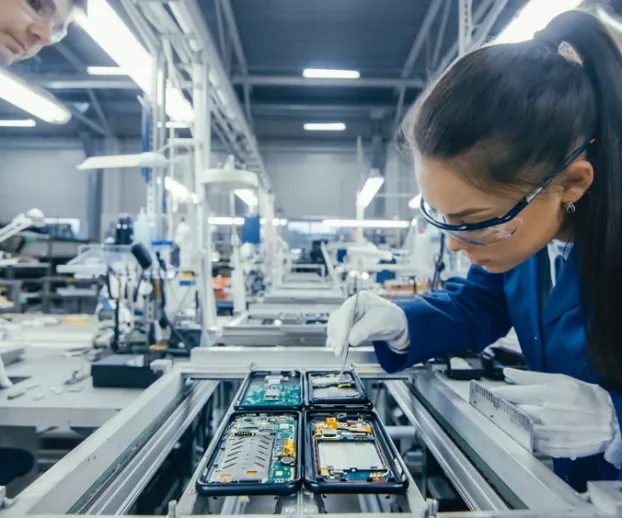

The all-in-one autonomous cleaning robot provides a comprehensive solution that includes scrubbing, sweeping, dusting, and degreasing. Its highly efficient system can clean up to 2000 sqm per hour, making it ideal for heavy-duty cleaning of large areas in industrial settings.